A pig slaughterhouse is an automated mechanical system

Linked by conveyor systems, it utilizes advanced equipment such as CO₂ stunning chambers, steam-scalding tunnels, and AI-guided splitting saws to efficiently convert live pigs into standardized carcasses. The design emphasizes animal welfare compliance, food safety rigor, and scalable capacity, balancing ethical practices with industrial efficiency.

Key Advantages of Modern Pig Slaughterhouse Equipment

✅Hyper-Efficient Throughput

✅Global Compliance & Animal Welfare

✅Zero-stress handling

What include in Pig Slaughterhouse?

✅Pig bleeding

✅Pig Carcasses

✅Pig Dehairing

Slaughterhouse Capacity

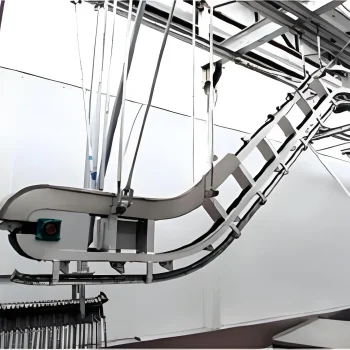

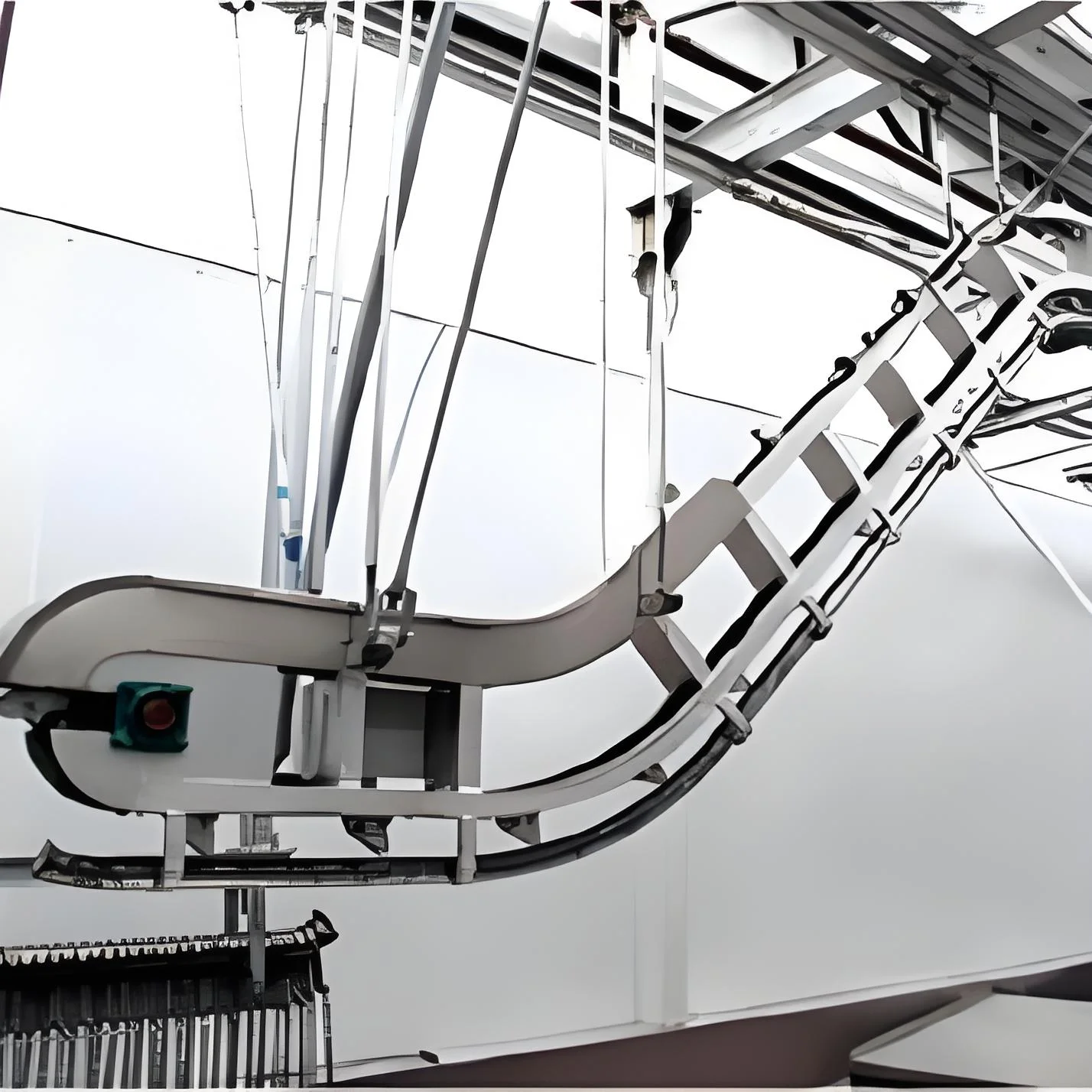

The pig bleeding system

Modern slaughterhouses widely adopt automated bleeding systems, which achieve efficient and hygienic bleeding operations through mechanical conveyance, precise stabbing, and blood collection.

Equipment includes:

✅Suspended conveyor chains

✅Rail-mounted conveyors

✅Bleeding knives/stabbing devices

✅Electrical stunning equipment

✅Cleaning devices

Advantages:

✅Ensures meat quality

✅Complies with hygiene standards

✅Enhances production efficiency

Our equipment can be flexibly combined according to customer needs to adapt to different slaughter processes and site conditions.

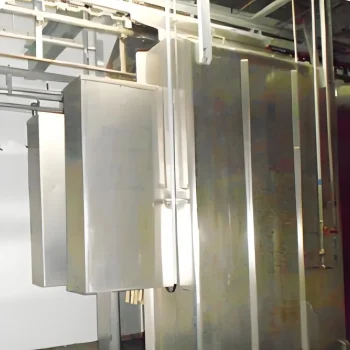

Pig carcass cleaning equipment

We offer a series of equipment for this purpose:

✅ Roller Brush Cleaning Machine

✅ Spray Cleaning Machine

✅ Carcass Patting Cleaning Machine

Features and Advantages of the Equipment:

✅ Efficient Cleaning

✅ Pollution Reduction

✅ Efficiency Improvement

✅ Compliance with Hygiene Standards

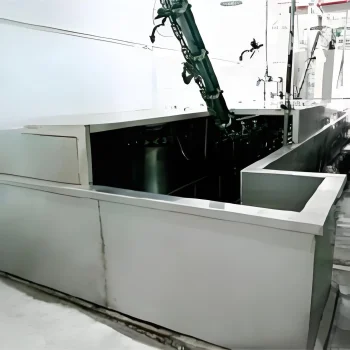

Pig dehairing equipment

Pig dehairing equipment is a key apparatus in slaughter processing, which removes pig hair through mechanical friction, scraping and other principles. There are various types such as scalding and dehairing machines (pawing machines here in a specific functional sense referring to this category in the industry context), spiral-type and hydraulic-type equipment, capable of enhancing dehairing efficiency, ensuring meat quality and complying with hygiene standards.

Our advantages:

✅Improving production efficiency

✅Ensuring meat quality

✅Meeting hygiene standards

Small-scale slaughterhouses can opt for 180-type or 200-type equipment; medium-scale slaughterhouses can choose 300-type or 400-type equipment; large-scale slaughterhouses can select 500-type or larger-specification equipment.